*견적이나 기타 궁금하신 사항은 게시판을 이용해 주십시요.^^

제품명 : PHARMACEUTICAL Autoclaves SERIES

(250,450,1040,2000,LITERS) PHARMACEUTICAL CARE

제조사 : TUTTNAUER / ISRAEL

-FEARURES-

Pharmaceutical Autoclaves Models

cGMP Pharmaceutical autoclave with fully automatic sliding doors designed to

conform to end-user requirements (URS) using steam as the sterilizing agent,

appropriate for pharma production and quality assurance processes. The T-Max

12 autoclave chamber volume is 1040 liters.

| Model |

Chamber

Dimensions

( Wx H x D)

mm |

Chamber

Volume (Liter) |

Door

Options

5596 |

| T-Max 12 |

660 x 1220 x 1295 |

1040 |

Horizontal sliding - 1 or 2

doors |

Autoclave

Features and Options

Standard ✓ Optional

o

| Pressure

Vessel |

| AISI 316L stainless

steel chamber |

✓ |

|

ASME Code Section VIII, Division 1

or PED 97/23 EEC |

✓ |

| AISI 316L stainless steel jacket |

o |

| Polished Surface (Ra less than 0.4 μm) |

o |

| Insulation encased in stainless steel |

✓ |

|

Jacket covering 100% of the chamber wall for

uniform heat distribution. |

✓ |

| Jacket cooling |

o

|

| Bio-shield preperation |

o

|

| AISI 304 or 316L stainless steel base frame |

o

|

| Door(s) |

| Automatic sliding door(s) |

✓ |

| Bi-directional door sequencing |

o

|

| Piping

& Components |

|

Pharmaceutical grade sanitary piping and

components (primary) |

o |

Pharmaceutical grade sanitary piping and

components (primary & secondary) |

o |

| PT100 temperature sensor in drain |

✓ |

| Sanitary 0.2 μm air admission filter |

o |

| Chamber water level & alarm |

✓ |

|

Isolated pressure (membrane) gauges |

o |

| Videoboroscoping report for clean piping |

o

|

| Air detector |

o

|

| Other |

| Clean steam generator |

o |

| Biohazard system for waste treatment |

o |

| Filter integrity testing connections |

o

|

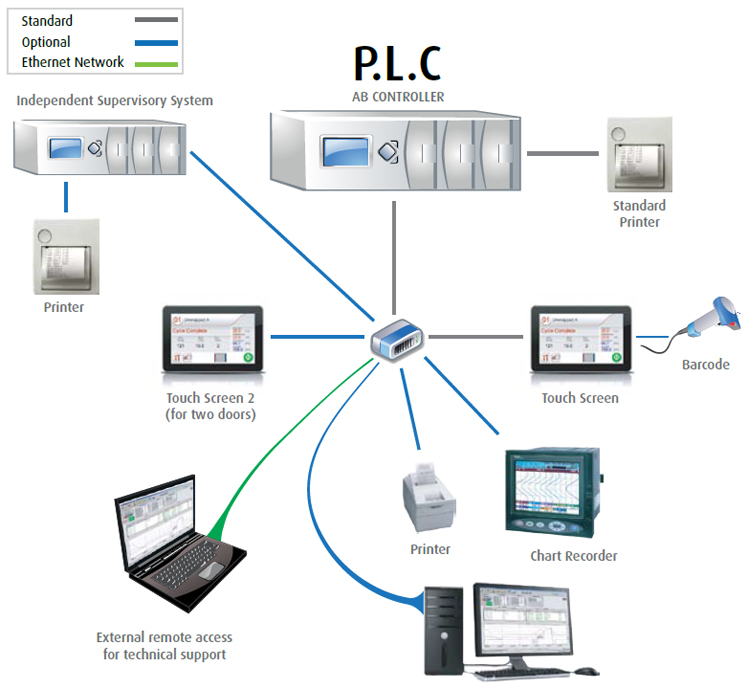

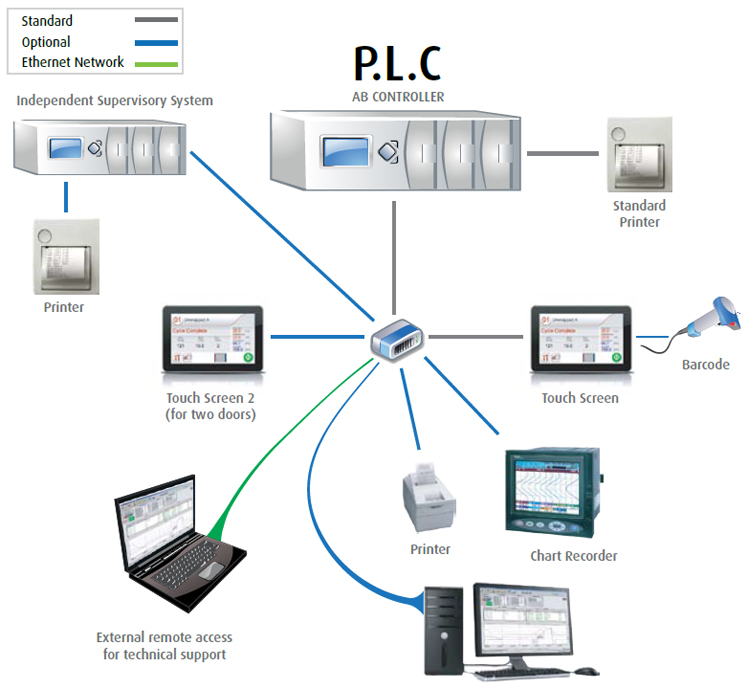

CONTROL SYSTEM

Advanced Control System

Take advantage of Tuttnauer’s sophisticated user-friendly PLC control system

based on the advanced Allen-Bradley platform in all pharmaceutical

autoclaves.

Standard Features

- 7" Multi-color touch screen for easy access to controls and information via

the panel

- Stores the last 200 cycles in built-in memory

- 4 access levels and 11 user passwords to control access/operation of the

autoclave

- In/Out test (enables technician to check each system component separately)

- Sterilization Temperature range 110°C to 137°C

- Ethernet connection for remote monitoring, remote maintenance, and software

updates

- Filter replacement notifications based on the number of cycles

- 21 CFR part 11

Optional Features

- 10" Multi-color touch screen

- F0 software control

- Up to 16 different Barcodes

Sophisticated Touch Screen HMI

The Human Machine Interface (HMI) has been designed with the following

considerations:

- Multi-color display for easy reading

- Easy operation

- Quick access to important information

- 26 Multiple languages

- Built-in view of historical cycle data

- Graphical display of Temperature and Pressure trend graphs

SCADA Software & Hardware

SCADA software (optional) allows for control and monitoring of up to 16

sterilizers on an external PC. The software retrieves data, creates graphs,

tables and printouts. Thousands of hours of cycle data can be stored in the

cycle history.

PROGRAMS

The advanced control system allows for customization of each program which

allows for a high degree of versatility, providing the flexibility of using the

same autoclave for many types of loads and applications. The controller has up

to 22 programs.

Tuttnauer thoroughly checks each program to ensure that they perform

according to our customers requirements (URS).

Unwrapped & Solid

- Utensils

- Glassware

- Machine Parts

Wrapped & Porous Goods

- Textiles

- Filters & Filter Vessels

- Elastomers & Rubbers

- Ampoules & Vials

- Instruments & parts (wrapped)

- Glassware (Wrapped)

Liquids & Media (Optional)

- Liquids (open)

- Liquids (sealed)

Biohazard (Optional)

- Pathogens

- Biohazard Waste

Test & Control

- Leak Test

- Bowie & Dick Test

- Filter Sterilization

- Filter Integrity Testing Connections (optional)

Design and Construction

The pharmaceutical autoclave line is designed and constructed for sanitary

pharmaceutical applications which require strict compliance with cGMP. All

machine components exposed to steam are made from 316L stainless steel.

Diaphragm Valves

Diaphragm valves and gauges are used to allow maximal drainability and

minimise the risk of contamination.

Specialized Piping

To meet the high sanitary requirements of the cGMP the pharmaceutical-grade

sanitary line (primary piping) to the chamber steam inlet is orbital

welded.

Sanitary Air Filter

A 0.2 μm air filter ensures that bacteria free air enters the chamber. A SIP

provision is available for the sanitary filter.

Air Detector

An optional air detector detects insufficient air removal and non-condensable

gases in the steam.

Chamber and Jacket Construction

The 316L Stainless Steal chamber inner walls have a mirror like surface level

polish less than 0.4 μm (specific polishing values are available upon request).

The chamber is constructed to be drainable with smooth, rounded and sloped

surfaces to enable proper drainage and cleaning.

The jacket is constructed from 316L stainless steel. The chamber is cooled

through jacket water cooling.